Mandates as Interim Manager

Managing Director ad interim

Starting Point:

- The small company was taken over by a medium-sized group in 2016 with the aim of expanding their products with telecommunications technology. This goal was not achieved for organizational and personnel reasons. The market changes in copper and fiber optic technology led to a decline in unit numbers and sales and ultimately to losses.

Task:

- Management of the company during the transition phase from the previous managing director to the successor solution

- Implementation of the annual financial statements for 2022 and implementation of the budget and business planning

- Management and control of sales, support of strategic customers and expansion of the customer base

- Development of a strategy for the future of the business and its implementation

Implementation:

- Operational management including key account management

- Analysis of the current situation regarding income statement, balance sheet, sales, product calculation, R&D results, market and competitor situation

- Creation of various strategic options for the management of the group, including a proposal for the most promising option

- Implementation of the strategy according to the decision

Results:

- Impairment analysis including necessary depreciation

- Production relocation

- Sale of parts of the company as an asset deal

- Integration of the GmbH into the sister company

- IT and CRM transition

- Separation of employees

- Site closure

Segment:

Telecommunications

Measurement- and Testdevices;

2,5 Mio. Euro Sales; 25 Employees

Reporting to: Executive Board of the Group

Interim Head of Technology

Reporting LIne: Chairman

Segment:

- Development and production of insulators for decontamination of filling systems for pharmaceutical companies.

- Sales: app. 80. Mio. Euro

- Employees: app. 200

Starting Point:

- Due to the strong growth (growth from 20 million euros in sales in 2019 to about 80 million euros in 2022), the projects could no longer be completed on time and in acceptable quality..

Task:

- Improve processes within the technology organization (R&D, engineering, production, and materials management) with a focus on automation (Rockwell/Siemens)

Implementation:

- Introduction of team structures and selection of suitable team leaders

- Daily intercompany shop floor meeting conducted

- Jour Fix with groups and team leaders

- Interface meetings, introduced for better coordination between the departments

- Introduced War Room Meetings to identify optimization potential for the project with delay.

- Improvement of resource planning, e.g., started by using a project management tool and central scheduling coordination

Results:

- The course was set for improved project execution, internal candidate was found to permanently fill the Head of Technology position and prepared for this position.

- Concept was developed to involve the top management level more closely in the management of the company.

Project Manager/ Consultant

Global Sourcing

Reporting Line: CEO

Segment: Process Automation: Control valves and devices for the process industry.

Sales: 661 Mio. Euro;

Employees: 4.500

Task: Development of a global network for sourcing & purchasing for 15 affiliated companies.

Starting Point: Various acquisitions have bought companies that have not yet been integrated. In the first step, the possibilities of a purchasing association should be analyzed.

Implementation: The project started with a workshop with participants from the various locations. This enabled me to immediately establish direct contact with the managing directors of the locations. During my subsequent visits to the various locations (DE, USA, ES, IT, RU, IN), I analyzed the situation on site in detail and recorded the requirements of the various plants. Together we developed 50 initiatives, including the introduction of a central data storage which allwoed us to determine the global demand for purchasing volume, e.g. for cast parts. For the castings I took part in the negotiations with the main supplier in Coimbatore/India.

Results:

- Establishment of a global purchasing team

- Data collection on the global purchasing volume

- Development of a central data storage Introduction

- Definition of key performance indicators

On the basis of this work, the flow of goods can be made more economical for the production companies in the future and a considerable amount of costs can be saved.

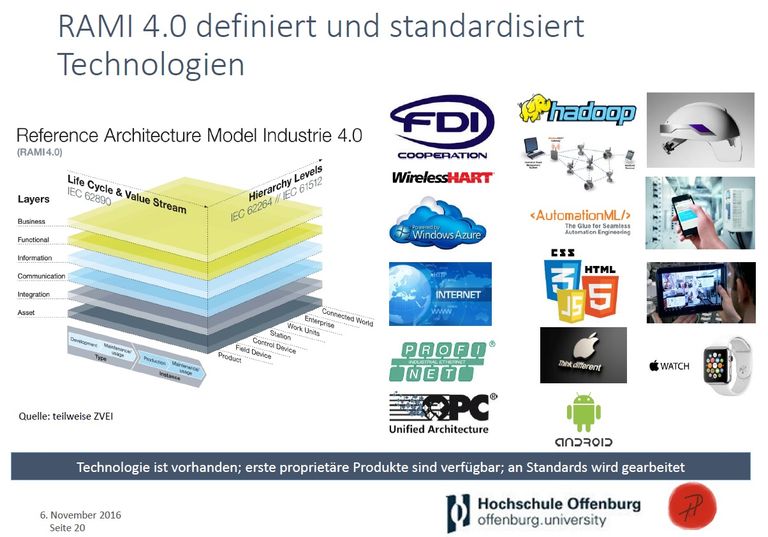

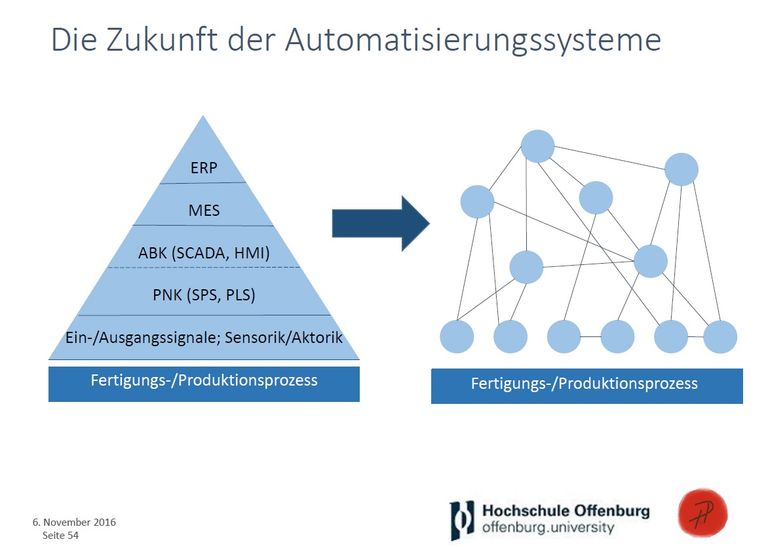

Lecture Automation Systems / Industry 4.0

Developing and holding the lecture ad interim until the new professor has been found.

Technologies of the 4th Industrial Revolution and their classification by the Reference Architecture Model Industry 4.0

The end of the Automation-Pyramid -> Cyber Physical Sytems

Permanent Positions

Analysis and adjustment of the strategy with subsequent implementation

Segment: Automotive-Supplier Industry

Sales: 150 Mio. Euro;

Employees: 850

Division Head, Managing Director Reporting to: CEO

Starting Point: Five strategies have been drawn up by various consulting firms over the past few years, but none of them have been implemented.

Implementation: My analysis of the situation showed that the different strategies had very similar results, however far too many actions were defined, of which hardly any initiatives were implemented. This was partly due to the fact that not enough employees were available to implement the numerous initiatives besides the daily business. The project managers were the department heads, who always showed in the reviews that the projects are "on track".As a first action, I therefore had to replace the project managers by specifying the people as project managers who actually did the work.

Together with the new project managers, I carried out a "deep dive" of the various strategy projects. In some projects it turned out that the assumptions made by the consulting firms were too imprecise. It started with the hourly rates and went all the way to the contribution margins. I stopped some strategy projects, revised others and implemented another set of initiatives directly. I have reduced the number of initiatives to what was feasible.

A major strategy project was the establishment of a production facility in the Czech Republic and the associated transfer of machines and products. In this project the Czech organization did not "pull" and the German organization did not "push" and thus little happened.

Like so often it was due to the people involved that I either replaced or was able to motivate to implement the transfer. I have changed the planning of the machines to be transferred, because in the original planning of the machines to be transferred required little manual labor and therefore a transfer did not bring any cost advantages. The problem was much more due to the lack of utilization of the machines and so I restarted a sales initiative to better utilize these machines.

Results: The strategic initiatives were reduced to what was feasible and implemented. The production site in the Czech Republic went into full operation. My regular reviews with the project teams that actually worked on the projects were essential for the success of the implementation.

Segment: Mechanical and Plant Engineering: Hydraulic Presses and Systems

Sales: 150 Mio. Euro; Employees : app.500

Managing Director/Division Head

Reporting to: CEO

Execution of major projects for the production of railway wheels

Starting Point: Two major projects in Kazakhstan and Turkey had to be put into operation at the same time. Both were already very late for various reasons, needed the same resources and new project managers had to be found.

Implementation: When selecting the project managers, the experience that “the chemistry has to be right” once again came into play. In one project, for example, I chose a project manager that my predecessor spoke out against very clearly. After weighing the pros and cons, I went with him anyway, which in retrospect was the right decision and was greatly appreciated by the customer.

Allocating the available resources was the biggest challenge. This was always a very difficult issue, especially in my negotiations with the subcontractors, but we were able to solve it satisfactorily by making compromises. A necessary decision was the full prioritization of one of the projects that is due for the official opening on “Industry Day” attended by the country's President. To motivate our employees to reach the very ambitious deadline, "only" for a political event, was challenging but I succeeded. The opening was a complete success and still leads to further orders with the customer today.

The cultural differences between Germany and Turkey and Germany and Kazakhstan/Russia should not be underestimated either. Here it helped to use commissioning engineers who originally came from these countries and therefore spoke the language and knew the culture. In my monthly project meetings with the customers' managing directors, the cultural differences, e.g. how do I address a problem, always had to be taken into account. I succeeded in this and was able to build up a friendly relationship with a managing director.

Results: Both projects were carried out very successfully until shortly before final commissioning. Then came the Covid 19 pandemic and caused another delay in project execution.

Development and construction of a cost-effective forming press in China for the Chinese market

Starting Point: The Chinese market was supplied with products from Germany. Although some of these were produced in China, they were based on German design. The local competitor products were significantly cheaper and we could hardly sell a press from Germany anymore.

Implementation: There were two challenges to be solved at the beginning. The German organization had to be convinced that this was necessary and feasible and the Chinese organization had to be put in a position to implement it. The German organization was convinced because I was able to show that I had already successfully developed and produced in China in the past. Furthermore, I was able to win a few key people who supported the project with full conviction.

Competent employees had to be found on the Chinese side. Here, together with the local management, I was able to recruit a very good development manager and sales manager. The local Chinese management is very important as they need to find and hire the rest of the project staff.

The next challenge was to motivate the Chinese colleagues to develop a forming press that does not correspond to the high-tech presses from Germany, but "only" meets the requirements of the Chinese customers.

After these hurdles had been overcome, it was just a matter of "normal" project handling with regular project reviews, which mostly took place remotely.

Results: A press was developed and built that was 40% cheaper than the original product from Germany. The market launch was successful and further presses are being developed locally for the Chinese market. The same approach was then implemented for presses for the American market with the unit in Brazil.

Segment: Mechanical and

Plant Engineering: Hydraulic Presses and Systems

Sales: 150 Mio. Euro; Employees: app.500

Division Head,

Managing Director

Reporting to: CEO

Growth Initiative Europe for Europe

Segment: Process Industry

Sales: 1.8 Bio. Euro; Employees: 4,000

Regional Division Head, Managing Director

Reporting Line: CEO Country/Region

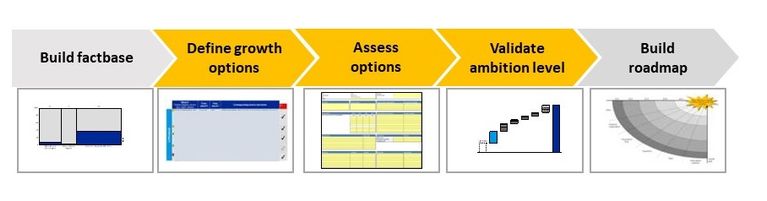

Starting Point: While Asia and North America experienced strong growth, Europe stagnated. For this reason we had to actively approach the market in order to generate growth.

Implementation: Europe was divided into three regions in this company: Northern Europe, Central Europe and Southern Europe. Each division had regional division heads. I was responsible for the Central Europe region for the Process Automation Division. The strategy project was rolled out across all divisions and all European regions.

Starting Poing: The starting point was the identification of the available market to capture the facts. The representation in the Mekko diagram is very helpful here. Defining the growth options is the hardest part. Here we developed ideas in various workshops – internally and with customers – which we then evaluated. With the promising initiatives, we have defined the aspirations for our growth and, based on this, created a roadmap for implementation. Europe is a very mature market, so much of the initiative has been in the area of after-sales service.

Since we didn't want to roll out the initiatives in all countries at the same time, we divided the implementation into different waves. In the first wave, we selected Germany, Poland, Austria and the Benelux countries for Central Europe. There were project managers for each country and initiative who were responsible for implementing the initiatives. I continuously tracked the implementation for my region and regularly presented the results in the overall project.

Results: Through this growth project, we were able to increase the order intake for Central Europe for Process Automation by $144 million.

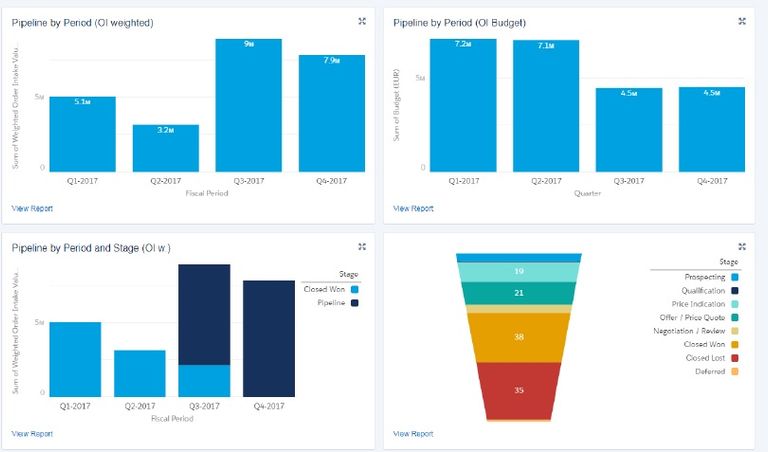

Optimization of sales processes, Introduction of the Customer Relationship Management software Salesforce

Segment: Industrial Systems

Sales: 160 Mio. Euro; Employees: 270

Chief Sales Officer, Managing Director

Reporting to: Division Head

Starting Point

The Industrial Systems Division consisted of various acquired companies that acted completely independently. The sales processes were completely different or non-existent.

Results

Very easy to use CRM system that meets the requirements of the division and maps the new, joint sales process.

Implementation

Determination of the sales contact person for each business unit and clarification of the sales processes. Salesforce was selected as a suitable CRM system for the entire company. Selection of a suitable CRM implementation company based on the desired agile SCRUM implementation process. Creation of the so-called product backlog with input from all sales units.

Weekly meetings with the implementation team where we defined the product backlog items to be implemented in the upcoming sprint. Weekly progress review and monthly presentation of progress to company owner and executive board. Gradual rollout of the CRM system to the various sales units.

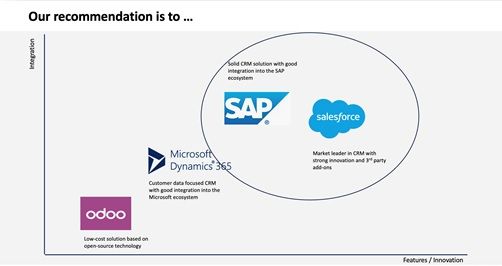

Selection of a suitable CRM system for the division and the group

Segment: Medium-sized business

Sales: 400 Mio. Euro; Employees: app. 3.500

Division Head, Executive Board Member

Reporting to: CEO

Starting Point: The various divisions of the group were either using outdated CRM systems or none at all. The aim was to select a uniform CRM, which would then be used in one division in the first step.

Implementation: Create a requirements list with input from all divisions, the different functions that will use the CRM and the IT department. Selection of an external consulting company to support the CRM evaluation. After the long and short list, two CRM systems were up for final decision – SAP Sales Cloud and Salesforce. Although Salesforce is the better CRM system from my point of view, I made the decision in the direction of SAP, since SAP was the more suitable CRM system for the entire company (experience in some divisions, SAP ERP in use, etc.)

Result: The most suitable CRM system was selected for the group of companies.

Industry 4.0:

Identification of product ideas and their piloting

My Industry 4.0 experience started when I started my career at the research center in the area of "deep learning" (e.g., neural networks). As a technology manager, I led the development of an automation system with the so-called "Aspect-Object" technology, which is very similar to the Industry 4.0 concept of the administration shell (Verwaltungsschale). In my roles as BU and division manager, I have developed product ideas in the field of Industry 4.0 in various workshops with customers, for example using the "Business Model Canvas" method.

I implemented the ideas developed together with customers as part of pilot projects. Ideas such as the use of "smart helmets" are already being used in many companies today. Other ideas, such as semi-autonomous operation of chemical plants, will still need some time to mature. Virtual engineering and virtual commissioning are already being increasingly used under the term "digital twin". I have published my experiences in digitalization and Industry 4.0 in numerous publications and lectures.

Division restructuring and site closure

Segment: Mechanical and Plant Engineering: Hydraulic Presses and Systems

Sales: 150 Mio. Euro; Employees: app.500

Division Head, Managing Director

Reporting to: CEO

Starting Point: With a turnover of 150 million euros, in every annual budget meetings with the parent company we discussed whether it was worth being an independent division, especially since some products were substituted by new technologies. Due to the automotive crisis and the Covid-19 pandemic, incoming orders fell dramatically, so action had to be taken.

Implementation: I came up with four options. Continuation of the division at a lower sales level, redistribution of the tasks of two divisions, complete closure, or restructuring and integration of a remaining working organization into another division.

The first option was not viable because the division's overhead and lower sales would not have made it possible to achieve a sustainable positive result. We rejected the second option because the turnover of the entire company had fallen and the reduction by one division was therefore advantageous. Preferred option was to restructure and integrate into another division as this allows the remaining business to continue to be processed. In order to reduce costs, I included the site closure in this model, since the new size of the unit did not justify an independent location and there was enough space at the location of the other division to accommodate the employees.

The challenge in this scenario was to retain the key people. We were able to make this clear in the negotiations with the works council and, after long negotiations, the works council agreed to a so-called list of names (Namensliste), which made it possible to define the people who had to leave the company or stay in the company. Creating such a list of names is always a compromise. However, I managed to create the list together with the works council and thus maintain a functioning organization. We then negotiated the reconciliation of interests and the social plan and implemented the restructuring and site closure.

Results: Through the list of names, it has been possible to obtain a functioning organization that can continue the business as a business unit in a new division.

Restructuring of the R&D organization with the goal of 25% cost savings, establishment of R&D in Bangalore/India

Segment: Automation Technology

Sales: 130 Mio. Euro; Employees: 700

Technology Manager

Reporting to: BU Manager / Division Head

Starting Point: With development locations in the high-cost countries USA, Sweden and Germany and several different automation systems, the development costs amounted to almost 50% of sales.

Implementation: Before I could start restructuring the R&D organization, a migration strategy had to be created to reduce the number of automation systems. The goal was to come to a common, uniform system in the medium term. This was a very complex process as there were good reasons for the different systems and why they work differently. However, we managed to develop a migration strategy to a unified system that took into account the specifics of the different markets and enabled a gradual migration.

With this strategy, I was able to develop a new set-up for the development organization. It was elementary that I could motivate the development manager to go along with the new R&D strategy. I succeeded in doing this by giving each location a clearly defined role and thus a future. In Bangalore/India we set up a new R&D organization with focus on software development and system testing. At the same time we have drastically reduced the number of employees in the USA, DE and SE in order to reduce costs. The key to success for building up the competence in India was that we were able to attract 7 expats who went to Banglore to transfer the knowledge.

Results: A well-functioning, global development organization for decentralized development with 25% lower costs.

Strategic development of the

global service business

Starting Point: The power generation business had offices in 30 countries. However, most of the local units focused on new business. In particular, the small countries only took care of the service business when no new system was awarded.

Implementation: Together with the Division Service Head, I have developed a concept for how we can systematically determine our installed base in the 4,000 power plants that use our technology. To do this, we created a questionnaire with which we were able to record the essential data, e.g. identification numbers of assemblies or software versions. Next, we defined a plant responsible person for each power plant who - similar to a key account concept - was responsible for a power plant. Ideally, we had a service contract with the power plant operator and the employee was on site most of the time. This has the advantage that we also get direct information about planned investments etc. and are therefore included in the offer process at an early stage. We traveled to the site to train the employees responsible for the plant and conducted trial interviews at selected power plants. In order not to lose focus over a longer period of time, I had regular reviews with the local units.

Result: Significant increase in profitability and sales of the aftersales service business.

Segment:

Power Generation Sales:

225 Mio. Euro; Employees: 765

BU Service Head

Reporting to:

BU Manager /

Division Service Head

Mobile/Hybrid Work

Segment: medium-sized business

Sales: 400 Mio. Euro; Employees: app. 3.500

Executive Board Member

Reporting to: CEO

Task: Decision regarding the introduction of home office (mobile working)

Starting Poing: Very different views regarding corporate culture and the use of home office

Intensive discussion in which I was able to show a positive influence of home office on work performance through fact-based studies, e.g. Bachelor Thesis of Sandra Huber „Invieweit beinflusst Telearbeit die Arbeitsleistung von Mitabeiter?“,

Result: Mobile working was introduced in a pilot phase by majority decision.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.